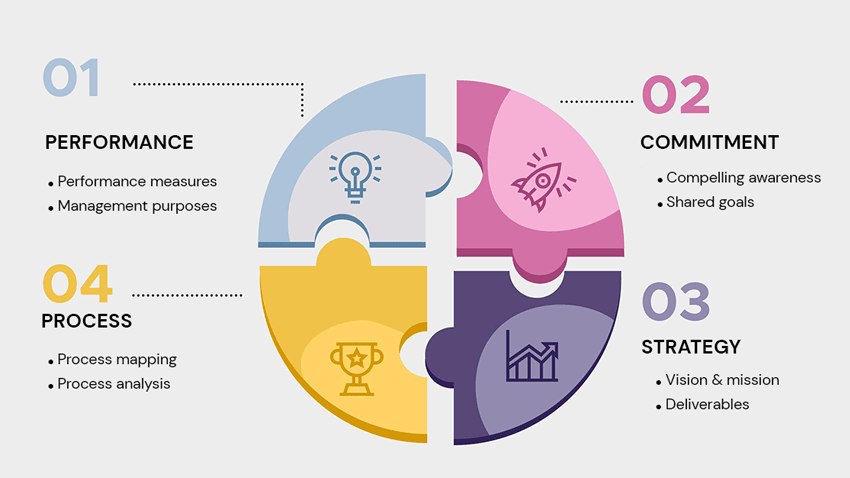

Ensures work meets or exceeds standards and identifies and implements ways to make job tasks or processes more efficient. A continuous improvement strategy is any policy or process within a workplace that helps keep the focus on improving the way things are done on a regular basis.

Continuous Improvement A Kaizen Model Creative Safety Supply

Kaizen is a Japanese business philosophy that focuses on continuous improvement and involves all employees.

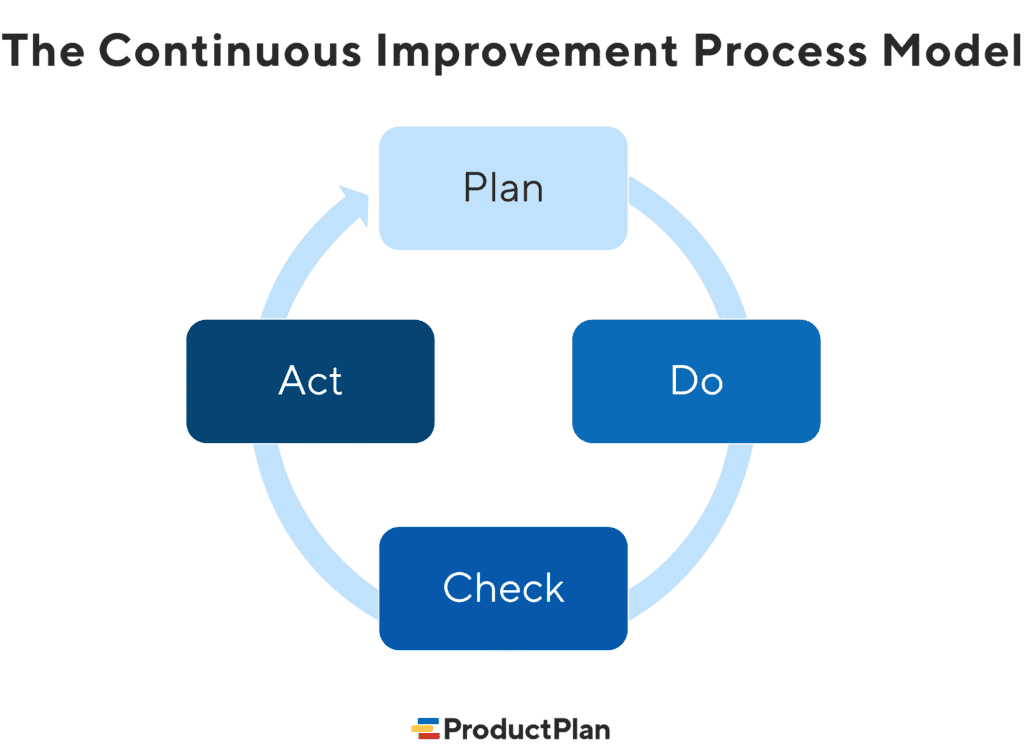

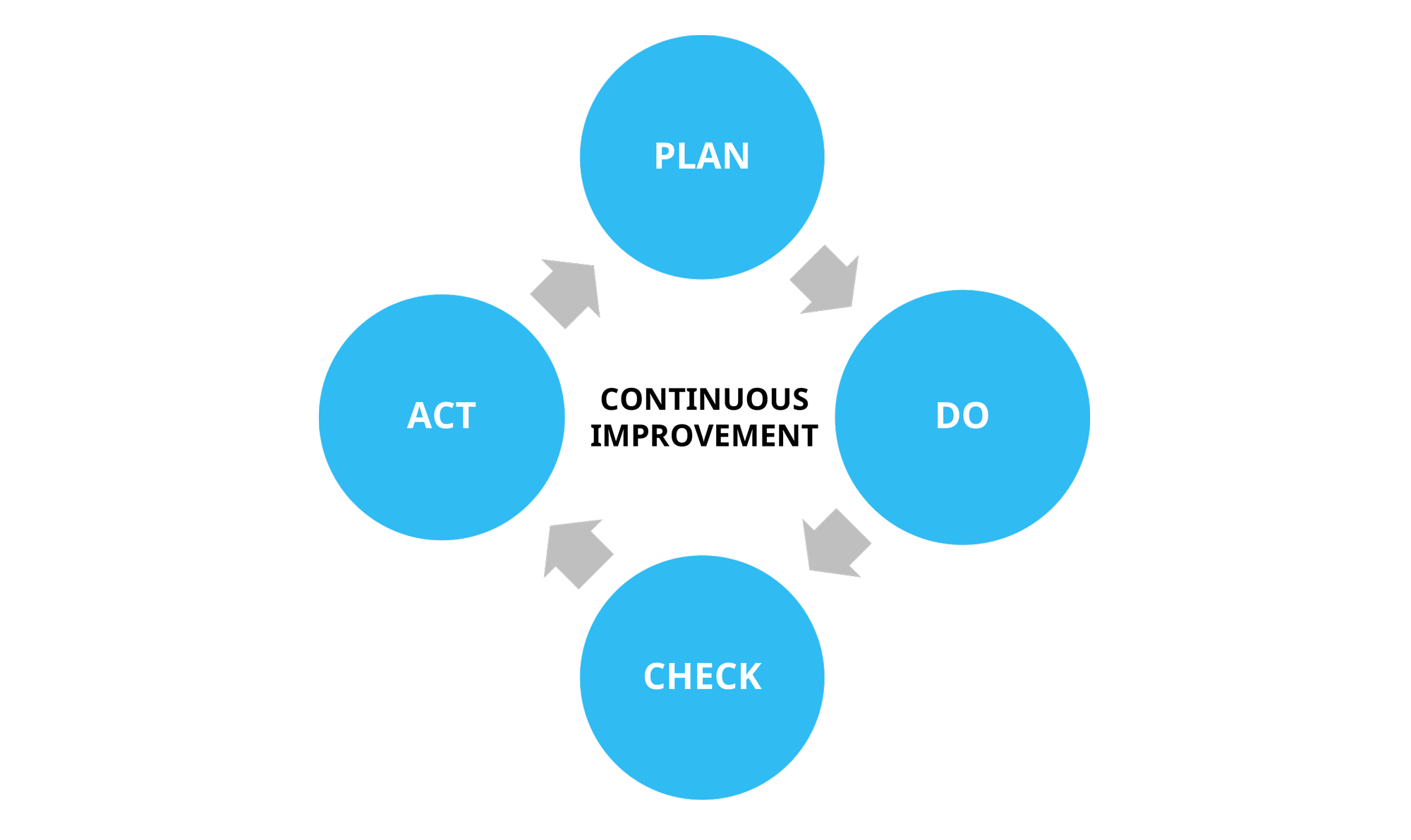

Continuous improvement efficient and. While there are many formalized approaches to continuous improvement such as the Kaizen or AgileLean methodologies you may also choose to implement a more informal approach to continuous service improvement. Continuous improvement also referred to as continual improvement can be defined as a practice of constantly re-examining how you work to bring ongoing incremental improvements to work processes. The concept of continuous improvement is an important element found in both Lean and Agile practices.

Once again you dont necessarily have to implement a formal program. Continuous improvement is a method to make sure that your processes methods and practices are as efficient accurate and effective as possible. In the Seven Principles of Lean Development continuous improvement is weaved throughout.

The principles of Building Quality In and Reducing Waste for example require a. Kaizen comes from two Japanese words. Kai improvement and Zen good which translates to continuous improvement.

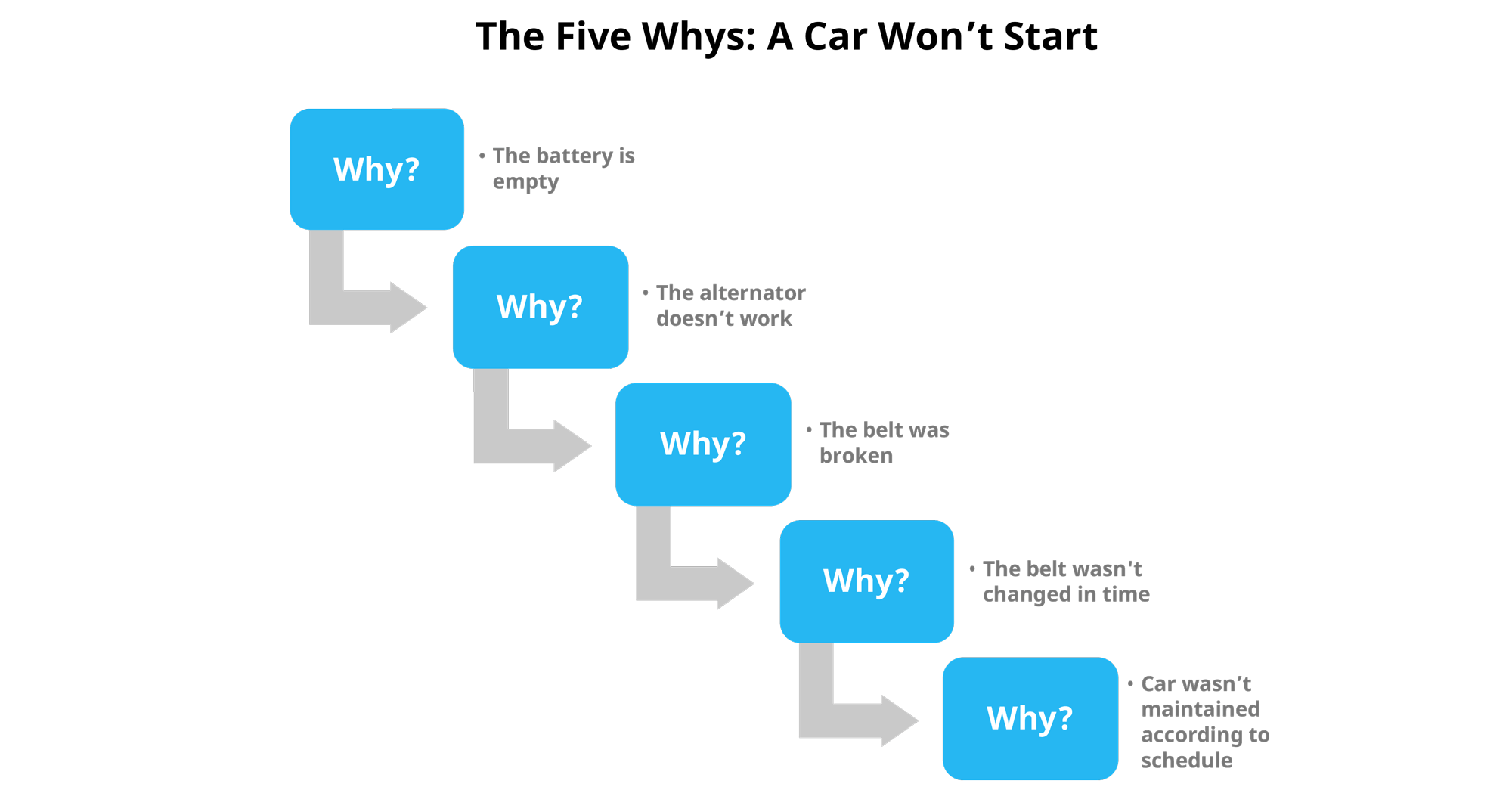

When you remove wasted motion unnecessary tasks and time-consuming components your processes become more efficient and effective. Much of SDSUs focus on continuous improvement and efficiency in the past five years has been in three areas. Its about finding a rhythm that works for your organization.

This methodology is important to scale processes and do so with greater efficiency and profit. Its about changing everyones mindset to a systematic way of finding better ways to do things. This is a four-step quality model that focuses.

As the saying goes those who ignore history are doomed to repeat it. It involves making the work environment more efficient and effective by creating a. 10 Ways to improving your workplace.

This is done surprise surprise by periodically examining and improving your processes to smash bottlenecks use the best software and take advantage of the most efficient methods. Continuous improvement requires the participation of everyone in the organization. Simply put continuous improvement is important because its the best way to ensure that were doing things the most efficient effective and productive way every single day of the week and on every single component that were working on.

The first and most obvious benefit of continuous improvement is that you will have more efficient operations. Continuous improvement isnt about setting a high pace. And we make history every.

Above all to find out how to work better as a team. This could be through regular incremental improvements or by focusing on achieving larger process improvements. Under direction implements ways to make job tasks or processes more efficient.

From a catering operation to a car wash business these firms must regularly measure customer satisfaction and observe activities in order to identify opportunities to improve results. Understands job tasks or processes and their impact on goals and objectives. View our 10 Continuous Improvement Strategies that Work SlideShare presentation.

In service-focused industries continuous improvement is implemented to improve efficiency and strengthen the quality of service delivery. Alex Hulshof May 06 2015. Lets explore the top 10 continuous improvement strategies that have proven to deliver results when implemented correctly and with dedication.

1 utility infrastructure 2 applying software applications to reduce or eliminate paper-based processes and 3 making process enhancements using a continuous improvement or lean framework. Lean is a Japanese Toyota philosophy in which every one of the company focuses on creating value for the customer by minimizing waste. This includes the executive suite management and line workers.

5S continuous improvement kaizen events value stream mapping pdca go see etc are all part of the lean toolbox to create value for the customer. Delivery processes are constantly evaluated from customers view of point and improved in the light of their efficiency effectiveness and flexibility. Continuous improvement is a proactive approach to superior customer service which prioritizes the elimination of waste and relies on active employee involvement to develop solutions to.

Cultivating a culture of continuous improvement means committing to an ongoing effort to improve services and processes. The continuous improvement program becomes effective when employees are engaged in developing the culture. Continuous improvement CI sometimes called continual improvement is the ongoing improvement of products services or processes through incremental and breakthrough improvements.

In business Kaizen refers to activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers.

What Is Capa And Why You Need It Operon Strategist Effective Communication Skills Personal Development Skills Change Management

We Provide Services Throughout The Robotic Process Automation Journey From Defining The Strategy To Continuous Improv Digital Enterprise Automation Enterprise

Kaizen Books Only The Best In Kaizen Continuous Improvement One Word Inspiration Kaizen Improvement Books

Continuous Improvement Definition And Overview

Online Webcast Key Concepts Of Lean Lean Sigma Lean Startup Lean Manufacturing

Sixsigma Google Sogning Lean Six Sigma Process Control Change Management

The Ultimate Guide To Continuous Improvement

Six Steps To Continuous Improvement Of Student Learning Student Learning Problem Based Learning Learning Theory

Pin On Lean 5s Workplace Organization

Life Cycle Assessment A Catalyst For Continuous Improvement And Complete Measurable Process To Minimize Life Cycle Assessment Life Cycles World Environment Day

Iso Cerfication Services Kaizen Process Improvement Leadership Management

What Is Continuous Process Improvement Cpi Cflow

Kaizen Culture Continuous Improvement Corporate Culture 8 Key Elements Kaizen Mindset Suggestion System Qu Kaizen Small Group Activities Lean Six Sigma

The Ultimate Guide To Continuous Improvement

Continuous Improvement Poster The Pdca Cycle Light In 2021 Process Improvement Swot Analysis For Students Change Management

Pdca Cycle How To Plan Change Management Leadership Management